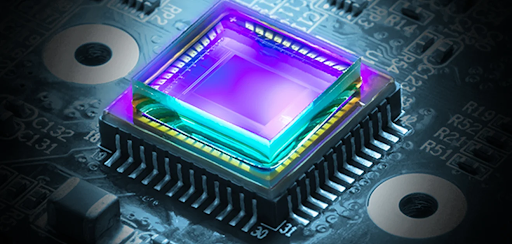

The semiconductors CCD and CMOS serve as “electronic eyes.” Although they both use photodiodes, the manufacturing method and signal readout technique differ. Although CCD technology was dominating at first due to higher sensitivity & picture quality, CMOS sensors began to overtake CCD sensors from 2004 onwards. Hence, today’s technology works on CMOS; this requires a CMOS image sensor test for a successful launch of high-tech products.

A Brief View About CMOS CMOS stands for Complementary Metal Oxide Semiconductor. The basic mechanism of a CMOS image sensor was developed in the late 1960s, but the device was not industrialized until the 1990s when microfabrication technology had evolved sufficiently. In today’s era, CCD (charge-coupled device) and CMOS image sensors are used in most digital cameras & mobile phones.

Before knowing the significance of test equipment, let’s understand why CMOS is growing over CCD.

What Makes CMOS Grown Over Decades?

➤Faster in Data Rate than CCD

A complementary metal-oxide-semiconductor image sensor contains a photodiode as well as a CMOS transistor switch for each pixel, allowing for individual pixel signal enhancement. The pixel signals may be accessed directly and consecutively and at a much faster rate than a CCD sensor.

➤Cheaper, Energy-efficient, and on-Chip Integratable

CMOS image sensors are less expensive to create than CCD image sensors. Unlike CCD sensors, which use high-voltage analog circuits, sensors use a smaller digital circuitry that consumes less power. CMOS sensors with on-chip image processing circuits are being developed for applications including image recognition & artificial vision.

Read More: Best camera cells in India

Why is CMOS Image Sensor Testing Important?

Product testing has an impact on product design and usability, as well as product marketing. Product testing has several major advantages:

- Ensures the product will perform to the standards & features.

- Make sure that customers may use things in the way they were intended.

- Identify competitive advantages and disadvantages.

- Improves product performance and customer satisfaction

- Assists in predicting product acceptability by customers.

- Data is collected to be used in the development of future goods.

By committing to extensive product testing, you can avoid any problems that may develop once the product is released. It’s the only method to tell how well your product will sell before it’s released. Similarly, image sensor testing helps the engineer identify the issues related to images and correct them before the product is launched on the market.

How is Automated Testing Helpful?

Traditionally, testing engineers need to perform the task manually. Despite making an effort, some sort of errors were still present. With the help of automated testers, the workload of the engineers has been reduced. The integrated software works on certain parameters and identifies the issues within a few minutes, which used to take a number of days.

Final Words

CMOS image sensors are widely used in today’s mobile phones and cameras. The prior testing of the image sensors becomes crucial to know whether the product is working according to the defined specifications or not. Hence, automated testing has helped engineers identify the issues in less time and ensure the launch is flawless.